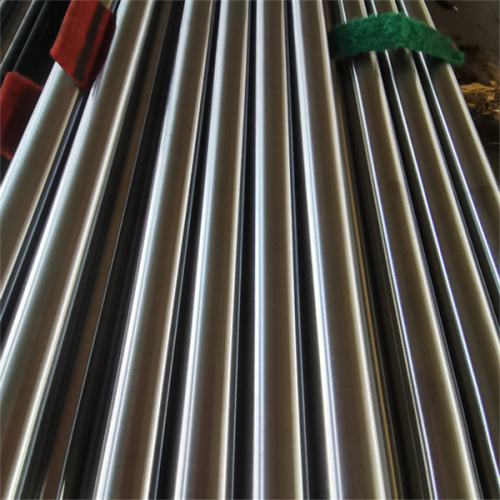

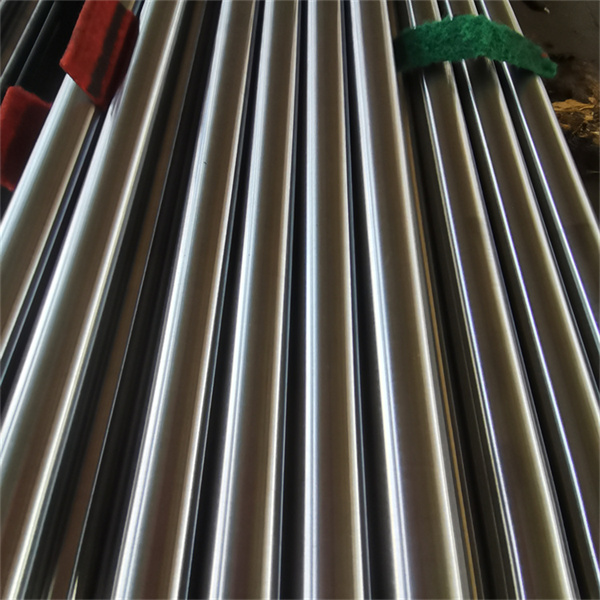

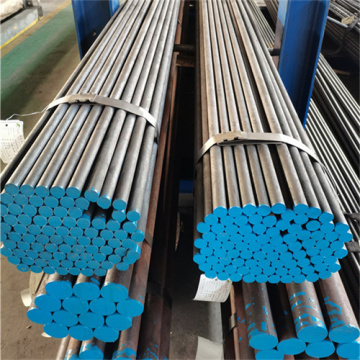

1.7225 turned, ground and polished steel round bar(42CrMo4+sh)

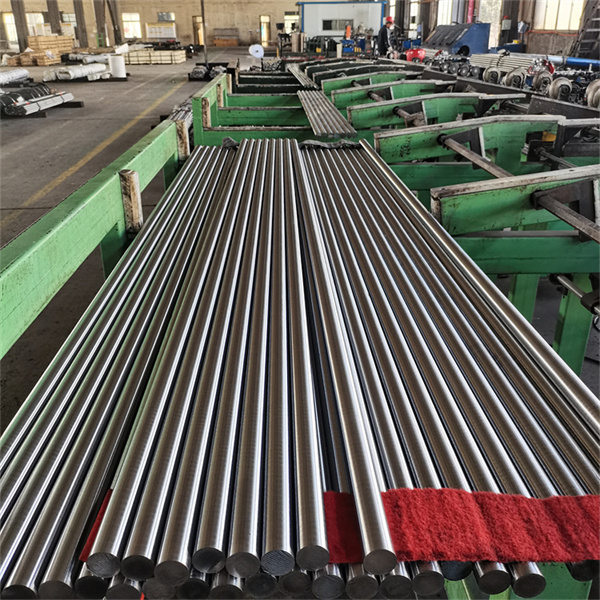

1.7225 Peeling or Turning Steel bar peeling or turning is a machining process used to remove surface defects in hot rolled steel bars. Closer diameter tolerances and glossy surfaces can also be obtained after peeling or turning. If ground or polished, the rebar will have a very good surface finish and can be used directly in production parts. 1.7225 Turned, Ground, Polished Precision Shafts are produced with 1.7225 cold drawn or hot rolled steel bars for precise dimensions and better straightness in the production of shafts. Straightness is very important for axis-controlled machining. 1.7225 turned and ground steel bars are used in the production of crankshafts, high-speed motor shafts, axle shafts, small shafts, etc.

Product Description

1. 1.7225 steel bar chemical composition:

| Materail | Chemical Composition % |

| DIN | C | Si | Mn | S | P | Cr | Mo |

| 1.7225 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | 0.035 max | 0.035 max | 0.80-1.10 | 0.15-0.25 |

2. 1.7225 steel mechanical properties:

| Mechanical Properties |

| Yield Strength (MPa) | Tensile Strength (MPa) | Elongation | Reduction of area | AKV (J) |

| 930 min | 1080 min | 12% min | 45% min | 63 min |

3.Our advantage of Cold Drawn Steel bars:

1.Precision size tolerance(h8, h9,h10, h11) 2.Good roundness 3.Good straightenss(0.2mm/m, 0.5mm/m, 1mm/m, 2mm/m) 4.Suitable sued mechanical properties (We can do heat treated according to final usage) 5.Good roughness to bright surface ( 0.4um, 0.6um, 0.8um) 6.More processing (Straightening, polishing, grinding) 7.Machinability is improved leading to a better tool life 8.No brittle, UT testing 9.Professional technical service 10.Competitive price 11.Fast delivery

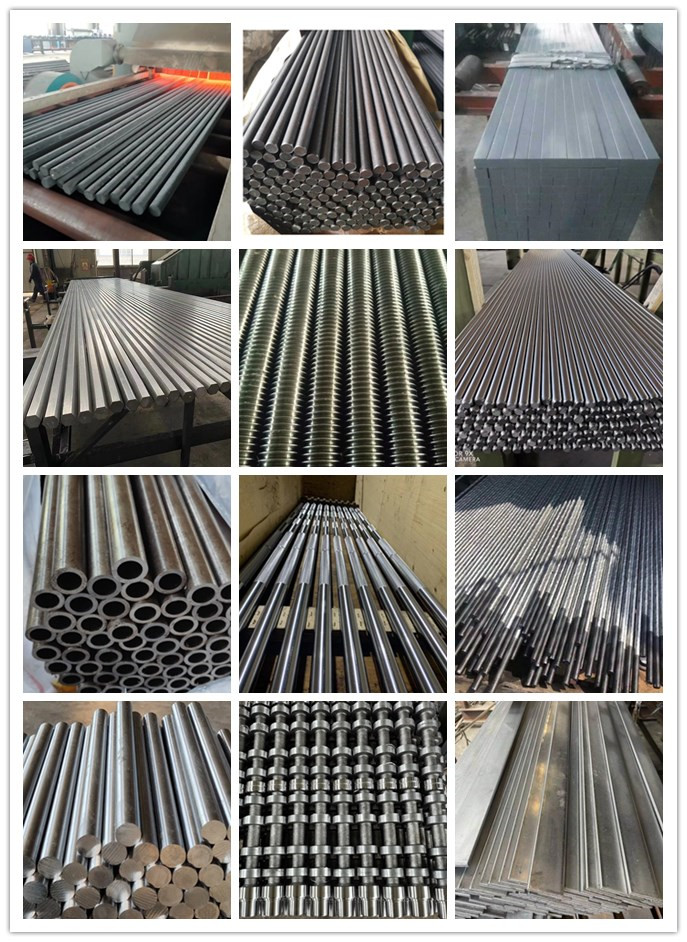

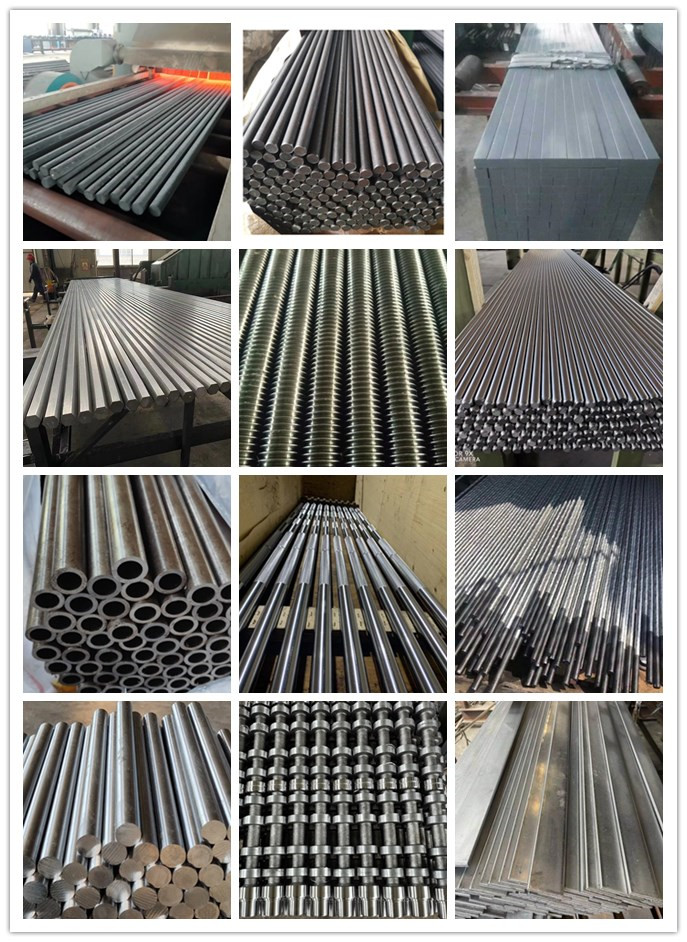

Other states and Applications

1.7225 hot rolled Round bars in other states can also be produced:

1.7225 42CrMo4 hot rolled Alloy Steel Round Bar

1.7225 42CrMo4 cold drawn alloy steel round bar(42CrMo4+c)

1.7225 42CrMo4 turned, ground and polished steel round bar(42CrMo4+sh)

1.7225 42CrMo4 quenched and tempered steel round bar(42CrMo4+qt)

1.7225 42CrMo4 Annealed Steel Round Bar(42CrMo4+a)

1.7225 42CrMo4 Normalized Steel Round Bar(42CrMo4+n)

1.7225 42CrMo4 cold drawn + quenched and tempered steel round bar(42CrMo4+c+qt)

1.7225 42CrMo4 quenched and tempered + turned, ground and polished steel round bar (42CrMo4+qt+sh)

1.7225 steel can be used for high strength stud bolt, Threaded Rods, wind power bolt, prestressed anchor bolts, post stressed anchor bolt, Steel Tie Rod, tie bar, tension rod, Tension Bar etc. Shaft, axle shaft, crankshaft, shaft for sleeve, linear shaft, pump shaft, rotor shaft, sensor shaft, spline shaft, drive shaft, mandrel shaft, transmission shaft, screw rod etc. CNC machines, precision CNC machines etc. Ejector pins and Ejector rods.

Packages:

In order to ensure that the surface of the product is smooth and defect-free, it is first packaged with plastic film to prevent corrosion during shipping, and then packaged with non-woven fabric or thick woven bag, or if the surface quality of the product is more stringent, we can use wooden boxes for transportation.

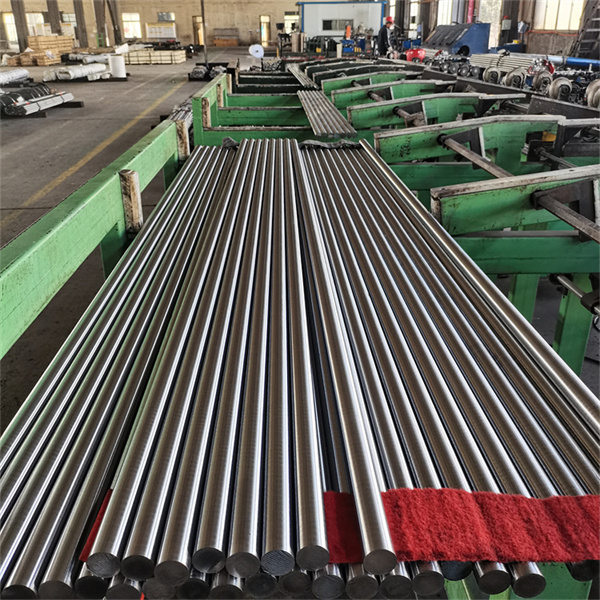

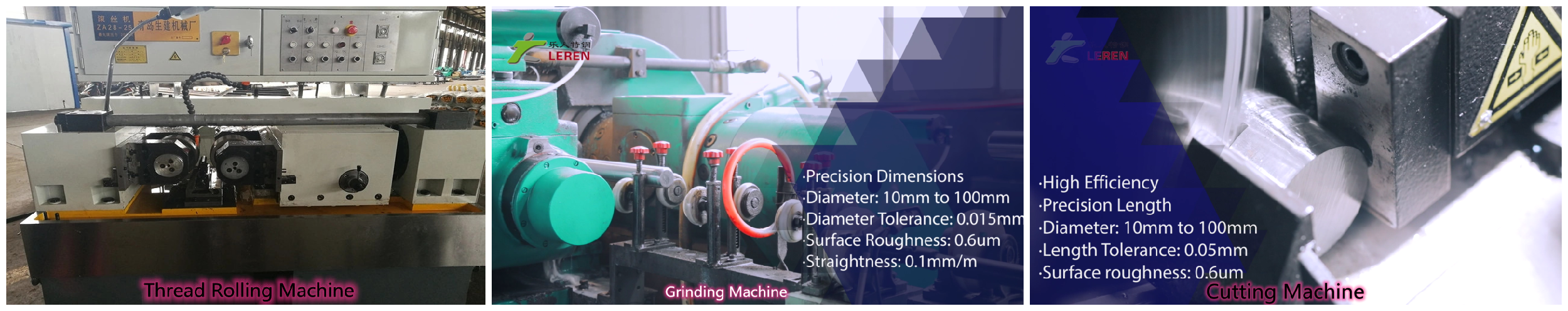

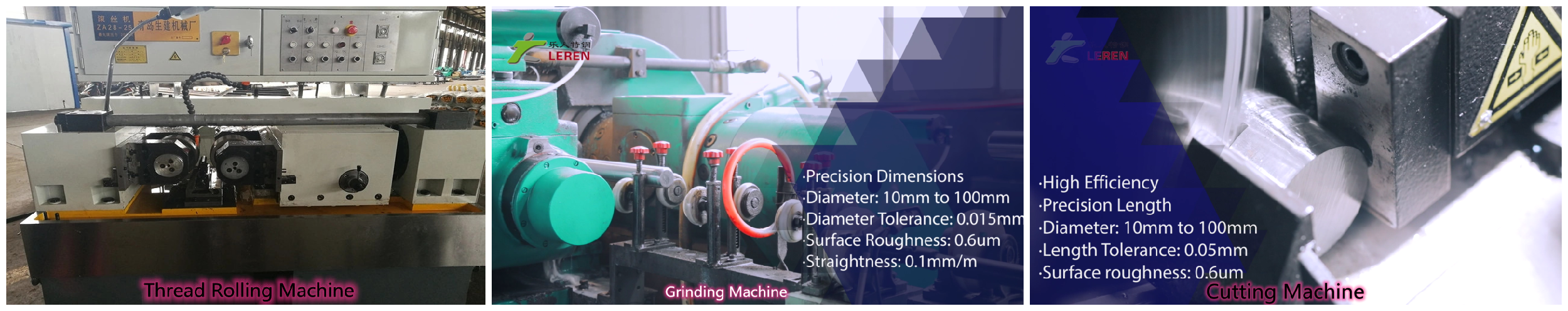

Our Factory And Inspection:

In March 2016, in order to meet the performance requirements of more customers, the company built a finishing line production line such as cold drawing, annealing, normalizing, tempering, peeling, fine grinding, chamfering, etc., equipped with complete experimental equipment and testing. equipment to ensure stable product quality. Strong production capacity, and constantly meet the personalized and professional requirements of customers.

If you are a trading company, we'd like to supply you the most competitive resources, the most suitable quality products, the techanical support to communicate with the end users. If you are a factory, we'd like to communicate with you on your technical specifications, we can supply you free samples for your trial testing or produce small trial order for your production. We aim to supply our customers teel solutions to decrease their cost and increase the commercial value. Our full sets of production facilities and complete testing equipments will support our aim.